What does HPP stand for?

HOMEPAGE/What does HPP stand for?

What does HPP stand for?

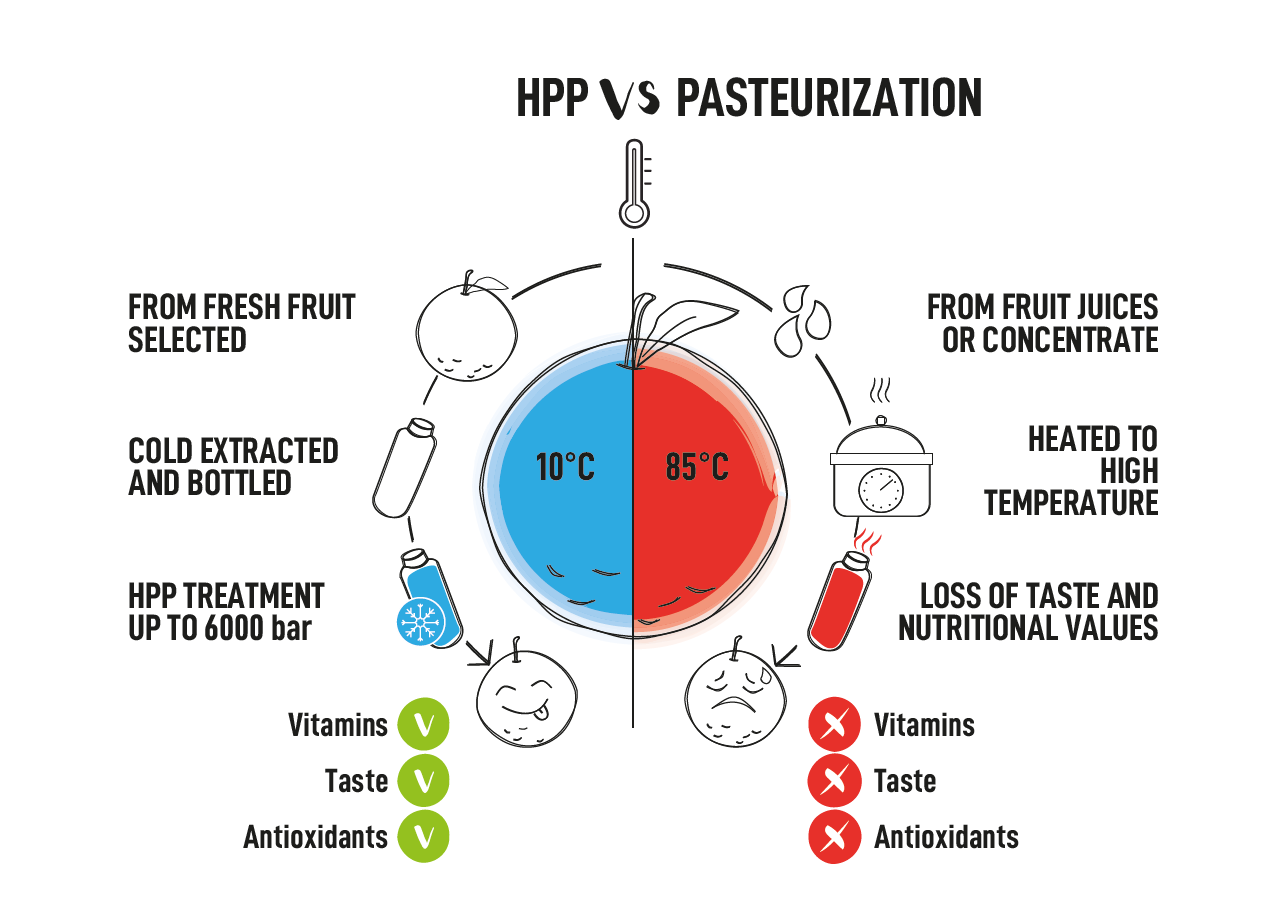

HPP - High Pressure Processing (or pascalisation) is a non-thermal food preservation technology that subjects our products (fruit juices, fruit creams, pestos and sauces, hummus and guacamole) to high hydrostatic pressures for 'cold pasteurisation' from unwanted microorganisms.In the case of juices, for example, once they have been cold-pressed and bottled, they are placed in a high-pressure chamber, where they remain for a few minutes at low temperatures at a very high pressure (around 6,000 Bar). In this way, the treatment guarantees a shelf-life of at least 60 days, while preserving the organoleptic and nutritional properties of the original ingredients. Studies confirm that there are twice as many vitamins and antioxidants as in pasteurised juices. (Barret D.M., Lloyd B.J. Sci. Food Agric. 2012; 92:7-22).

From the point of view of sustainability, HPP-treated products have the advantage of being fresh and at the same time have a longer shelf life than untreated products, thus reducing food waste and discards.

In addition to fresh fruit juices, we also use the same technology to produce:

𐤟 Fresh sauces

𐤟 Fresh fruit purees